Whether you are a plant owner or a plant constructor, whether your project concerns process automation, electrical engineering or functional safety - in large-scale expansion and new construction projects it is essential to have a strong partner along the way to digital progress, who understands your processes, works with you as a team and has a solid, comprehensive knowledge of all relevant technologies and standards. RÖSBERG has many years’ experience in efficiently coordinating with all project participants – from plant owner to project team to installation contractor, from process engineering to civil engineering to plant construction. In discussion with our customers and further project partners we proactively ensure that project targets are attained and processes run smoothly. Build on an integrated, future-safe concept with RÖSBERG.

RÖSBERG gladly takes on planning responsibility - in the role of a competent project partner in corporate projects, or as an experienced general contractor in projects for small and medium-sized enterprises. As an engineering partner in EPCs, or in the operator’s project organization. As a consultant, as owner’s lead, or as the responsible planner.

With partial or overall responsibility for our field of expertise, in reliable cooperation with all participants, we provide highly-qualified expert knowledge to complement your project team – especially in projects that are large-scale and complex. In the engineering process, and when equipping future-proof production plants, our digitalization competence ensures that you get high-performance manufacturer-independent solutions – reliably and fast.

Customers in many different sectors rely on us:

A well-thought-out FEED (front-end engineering design) for integrated process automation, electrical engineering and instrumentation is a major determinant for the success of plant projects. With our digitalization competence we quickly provide you with a sound, appropriatel basis. In line with our role in the project, we define the goals together with the team, and deliver a qualified basis for realization in our area of expertise. We research aspects of feasibility, evaluate risks and draw up an implementation schedule. Together with you, we create technically and economically strong concepts for optimal production and operations management based on a consistent automation solution, and for future-safe electrical engineering.

As well as the design of all necessary components, our engineers take on further specification and documentation tasks on the way to the vision of the operational plant.

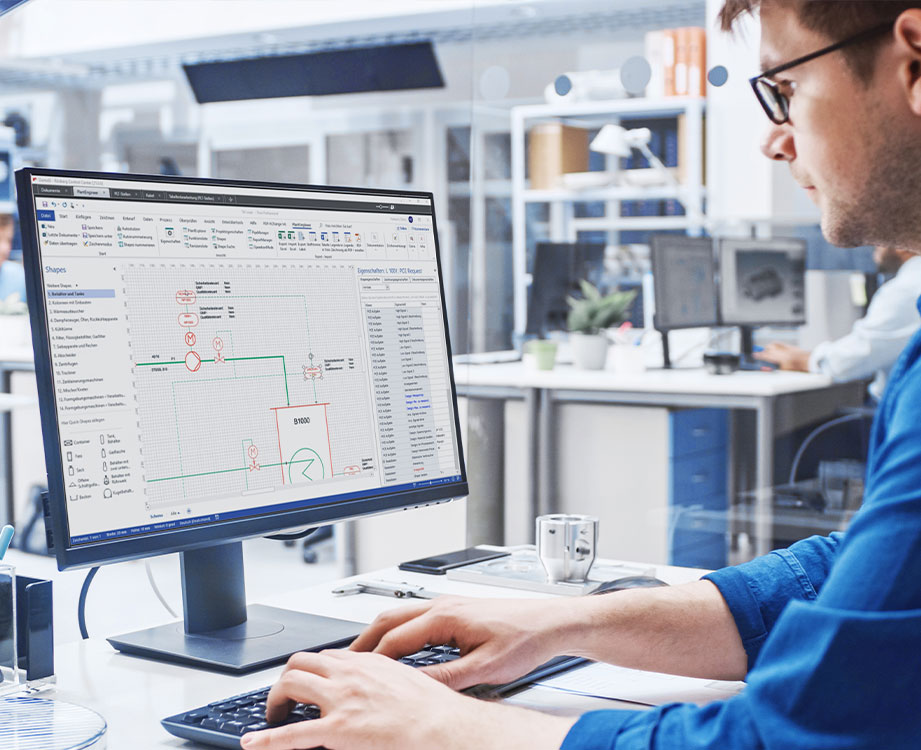

Starting with discussions on P&IDs and logic functions we create the data base for the CAE processing in the project and soon deliver important indicators and evaluations for the functional and non-functional planning, as well as important documents in the project such as PCT loop lists, energy consumer lists, logic diagrams and much more - of course revision-proof and following the iterative sequence. Here we use various differences sources, as far as possible without media interruption.

In the context of the overall project, we develop a dependable cost estimate and prepare our respective planning area for the final decisions. All participants benefit from our comprehensive understanding of complex, large-scale projects and sector-specific processes. Plan with RÖSBERG.

Our intelligent, consistent, data base-supported detail planning always bears time and cost efficiency in mind, and experienced PCT and ET experts provide technical design that is modification-friendly and installation-friendly.

Always in line with the current planning status, we support your procurement with detailed system and device specifications and talk to suppliers for a technical comparison of offers. We support you right up to the point or ordering - and take especial account of long lead items. As well as preparing all plant and installation plans - including switch rooms, control stations and cabinets - using state-of-the-art CAE systems, we give high priority in our detail engineering to accurate, practical installation documentation as well as final documentation. And of course, creating inspection documentation is also part of our work.

RÖSBERG is ready to act as a reliable partner for construction management, commissioning and start-up relative to the planning services it has performed. Familiar with the site and the project, we provide assistance in controlling that the implementation reflects planning and is compliant with regulations. We support you in the dynamic final phase of large-scale PCT projects: whether in the FATs for systems and devices, PCT functional checks, safety circuits (SIL) before first start-up or cold and hot commissioning and the necessary technical inspections. Our extensive use of digitalization for processes and documentation enables us to give the very latest statements on progress, matched by up-to-date documentation.

The documentation we provide at commissioning is transparent, optimally useable, and compliant with industrial safety regulations.

In special projects that are primarily concerned with our areas of expertise, RÖSBERG will take on the complete construction management if desired. Here we enlist the support of local partners with proven competence. Thus, our customers can rely on consistent end-to-end project implementation provided by our experienced team.

Bernd Rastatter

Head of Large Capital Projects E&I Engineering

Industriestraße 9

76189 Karlsruhe

Germany